What Is Modular Building Design?

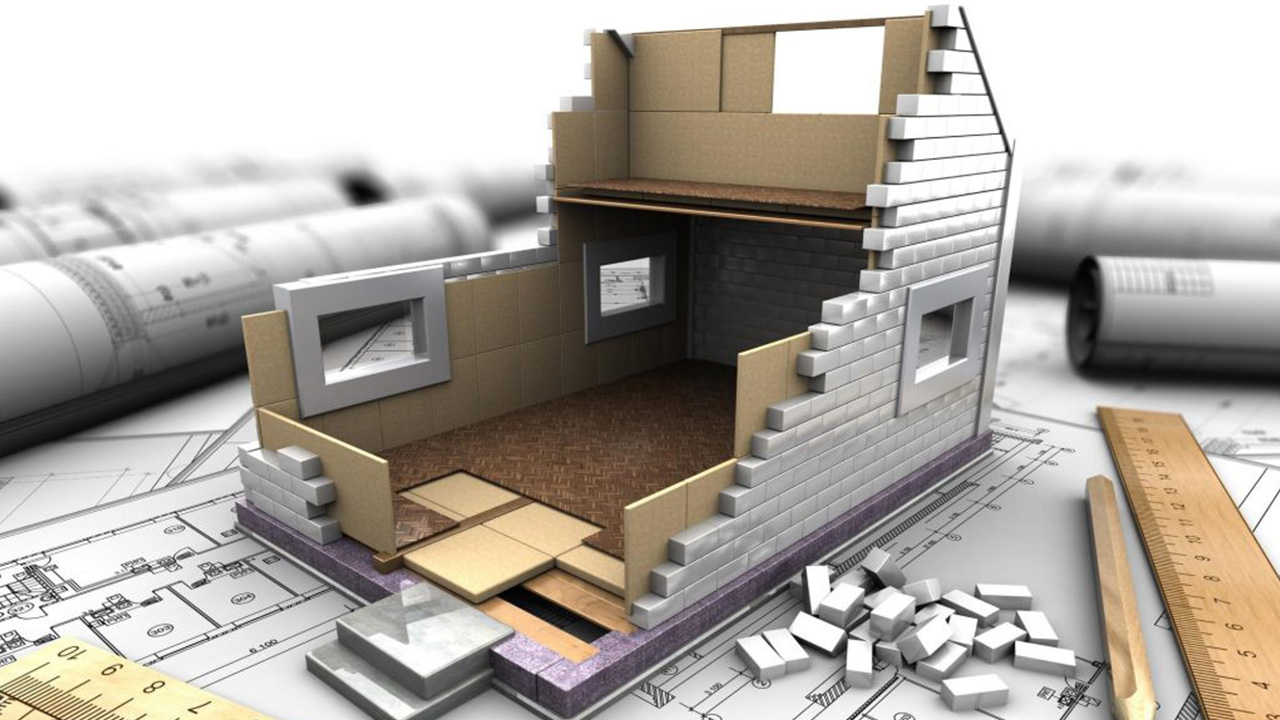

Modular building design involves creating sections—or “modules”—of a building in a factory setting before transporting them to the construction site for assembly. This method contrasts with traditional on-site construction, where everything is built from scratch.

With modular design, firms achieve higher quality control, faster assembly, and reduced disruptions from weather or site conditions.

Advantages of Modular Construction

Faster Project Timelines

When modules are manufactured offsite while site preparation occurs simultaneously, overall timelines shrink dramatically. Projects that once took a year can sometimes be completed in half the time.

Consistent Quality

Factory-controlled environments ensure better quality management. Errors are detected early, and standardized processes reduce rework.

Cost Efficiency

Although initial setup for modular methods may require investment, long-term savings come from reduced labor hours, faster project delivery, and less material waste.

Key Drivers of Modular Construction in Canada

Canadian cities face rising housing demands and sustainability goals. These factors are pushing adoption of modular construction.

Offsite Construction as a Solution

Offsite construction reduces site congestion and accelerates timelines, especially in urban centers like Toronto and Vancouver where land and labor costs are high.

Sustainability Benefits

Prefabrication often produces less waste and enables the use of eco-friendly materials, aligning with Canada’s push toward greener building standards.

How Cambulding Supports Modular Design

Cambulding empowers architects, engineers, and contractors with tools that integrate modular workflows into digital design.

Design Coordination

By linking modular layouts directly with mechanical design systems, Cambulding ensures that HVAC, plumbing, and electrical systems align perfectly with prefabricated units.

Time-Saving Automation

Cambulding’s automation reduces manual design errors, shortens approval processes, and keeps projects moving on schedule.

Real-World Examples of Modular Design

Case 1: Affordable Housing in Vancouver

Vancouver has adopted modular design to tackle housing shortages, completing projects 30–40% faster than traditional builds.

Case 2: Healthcare Facilities in Ontario

During the COVID-19 pandemic, modular construction allowed Ontario to deliver urgent healthcare facilities in record time, demonstrating the flexibility of this approach.

Challenges in Modular Construction

While the benefits are clear, challenges remain:

- Transport logistics for moving large modules.

- Regulatory hurdles, as not all municipal codes fully support prefabrication.

- Perceptions of lower quality, which are being disproven by recent high-performance modular projects.

Cambulding helps overcome many of these barriers by ensuring digital compliance checks and providing tools that validate designs against Canadian building standards.

The Future Is Modular

Modular building design is revolutionizing Canada’s construction industry by enabling faster, smarter, and more sustainable projects. As urban populations grow and demands intensify, modular methods will only become more essential.

With its cutting-edge digital tools, Cambulding is at the forefront—helping firms accelerate timelines, improve quality, and achieve greater efficiency.

Looking to fast-track your next project? Partner with Cambulding and explore how modular design can transform your construction process.

No comment